Nissan Rogue Service Manual: Charging system preliminary inspection

Diagnosis Procedure

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair battery terminal connection. Confirm repair by performing complete Charging system test using EXP-800 NI or GR8-1200 NI (if available). Refer to the applicable Instruction Manual for proper testing procedures.

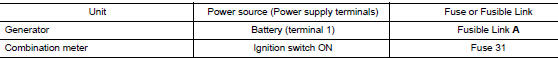

2.CHECK FUSE

Check for blown fuse and fusible link.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace the blown fuse or fusible link after repairing the affected circuit.

3.CHECK DRIVE BELT TENSION

Check drive belt tension. Refer to MA-13, "DRIVE BELTS : Tension Adjustment".

Is the inspection result normal? YES >> Inspection End.

NO >> Repair as needed.

Power generation voltage variable control system operation

inspection

Power generation voltage variable control system operation

inspection

Diagnosis Procedure

Regarding Wiring Diagram information. Refer to CHG-7, "Wiring Diagram".

CAUTION:

When performing this inspection, always use a charged battery that has completed

the ...

Other materials:

C1164, C1165 CV system

DTC Logic

DTC Logic

DTC

Display Item

Malfunction detected condition

Possible causes

C1164

CV 1

When a malfunction is detected in cut valve 1.

Harness or connector

ABS actuator and electric unit

(control unit)

Fusible link

...

P0863 TCM communication

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0863

CONTROL UNIT (CAN)

(TCM Communication Circuit)

An error is detected at the initial CAN diagnosis of TCM.

POSSIBLE CAUSE

TCM

FAIL-SAFE

...

Ambient sensor signal circuit

Description

It detects outside air temperature and converts it into a resistance value

which is then input into the combination

meter.

Diagnosis Procedure

Regarding Wiring Diagram information, refer to MWI-32, "Wiring Diagram".

1.CHECK AMBIENT SENSOR SIGNAL CIRCUIT

Turn ig ...