Nissan Rogue Service Manual: U1040 ENG comm circuit

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| U1040 | ENG COMM CIRCUIT (Engine communication circuit) | ECM cannot transmit a communication signal to generator. |

POSSIBLE CAUSE

- Harness or connectors (LIN communication circuit is open or shorted.)

- ECM

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted. always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Turn ignition ON and wait at least 10 seconds.

- Check DTC.

Is DTC detected? YES >> Proceed to EC-171, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK LIN COMMUNICATION CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector and generator harness connector.

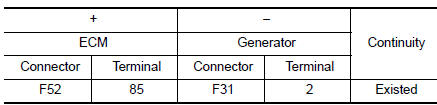

- Check the continuity between ECM harness connector and generator harness connector.

- Also check harness for short to power and short to ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

2.REPLACE GENERATOR

- Replace generator. Refer to CHG-20, "Removal and Installation".

- Erase DTC.

- Perform DTC confirmation procedure again. Refer to EC-171, "DTC Description".

Is DTC detected again? YES >> Replace ECM. Refer to EC-499, "Removal and Installation".

NO >> INSPECTION END

U1001 CAN comm circuit

U1001 CAN comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellen ...

U1044 ENG comm circuit

U1044 ENG comm circuit

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

U1044

ENG COMM CIRCUIT

(Engine communication circu ...

Other materials:

NISSAN Intelligent Key® (if so equipped)

Your vehicle can only be driven with the Intelligent

Keys which are registered to your vehicle’s Intelligent

Key system components and NISSAN Vehicle

Immobilizer System components. As many

as four Intelligent Keys can be registered and

used with one vehicle. The new keys must be

registered b ...

Door switch

WITH INTELLIGENT KEY

WITH INTELLIGENT KEY : Component Function Check

1.CHECK FUNCTION

Select "DOOR LOCK" of "BCM" using CONSULT.

Select "DOOR SW-DR", "DOOR SW-AS", "DOOR SW-RL", "DOOR SW-RR", in "Data

Monitor&quo ...

Floor trim

Exploded View

Rear floor trim (with third row

seat)

Rear floor trim (without third

row seat)

Floor trim hook

Front floor trim

Front floor spacer (RH)

Front floor spacer (LH)

Rear floor spacer (LH)

Rear floor spacer (RH)

Third row floor spacer (LH)

...