Nissan Rogue Service Manual: Differential side oil seal

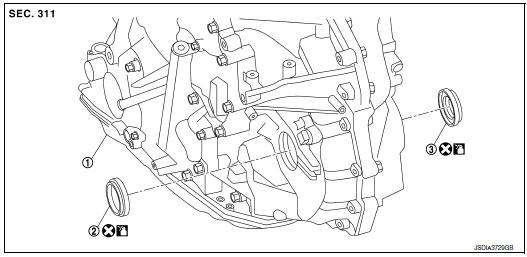

Exploded View

- Transaxle assembly

- Differential side oil seal (left side)

- Differential side oil seal (right side) (FWD models only)

: Always replace after every

disassembly.

: Always replace after every

disassembly.

: Apply CVT fluid

: Apply CVT fluid

Removal and Installation

REMOVAL

NOTE: When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

- Remove front drive shaft. Refer to FAX-18, "Removal and Installation (LH)" (FWD) or FAX-50, "Removal and Installation (LH)" [LH (AWD)]or FAX-52, "Removal and Installation (RH)" [RH(AWD)].

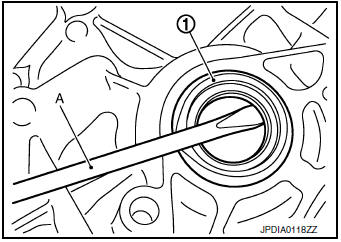

- Remove differential side oil seal (1) using suitable tool (A).

CAUTION: Be careful not to scratch transaxle case and converter housing.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse differential side oil seal.

- Apply CVT fluid to differential side oil seals.

- When inserting the drive shaft, be sure to use Tool.

Tool number: KV38107900

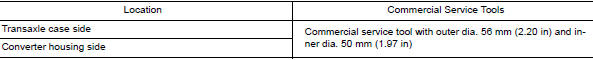

Install each differential side oil seal evenly using suitable tool so that differential side oil seal protrudes by the dimension (C) and (D) respectfully.

(A) : Differential side oil seal (LH)

(B) : Differential side oil seal (RH) (FWD models only)

Dimension (C) :Height difference from case end surface is within 1.8 ± 0.5 mm (0.071 ± 0.020 in).

Dimension (D) :Height difference from case end surface is within 2.2 ± 0.5 mm (0.087 ± 0.020 in).

NOTE: The reference is the installation direction of the differential side oil seal.

Drift to be used:

Inspection and Adjustment

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to TM-190, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to TM-192, "Adjustment".

Output speed sensor

Output speed sensor

Exploded View

Transaxle assembly

Output speed sensor

O-ring

Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: Apply CVT fluid

Removal and Installation

REMOVAL

...

Water hose

Water hose

Exploded View

Water outlet

Hose clamp

Water hose A

Clip

CVT oil warmer

Transaxle assembly

Water hose B

Heater thermostat

Water hose C

: Always replace after every

di ...

Other materials:

Front disc brake

BRAKE PAD (1 PISTON TYPE)

BRAKE PAD (1 PISTON TYPE) : Exploded View

Torque member

Bushing

Piston boot

Slide pin boot

Slide pin

Piston

Piston seal

Brake caliper body

Bleeder cap

Brake hose

Copper sealing washers

Inner shim cover

Inner s ...

Back door finisher

Exploded View

Back door

Access cover

Back door finisher

Clip

Pawl

Metal clip

Removal and Installation

REMOVAL

Using a suitable tool (A) release upper LH most clip, then

release remaining clips by gently pulling down on back door finisher

(1).

: Clip

INSTA ...

Cluster lid A

Removal and Installation

REMOVAL

Remove instrument lower panel LH. Refer to IP-22, "Removal and

Installation".

Remove instrument finisher A. Refer to IP-15, "INSTRUMENT FINISHER

A : Removal and Installation".

Remove instrument finisher B. Refer to ...