Nissan Rogue Service Manual: Brake pedal position switch

Component Function Check

1.CHECK BRAKE PEDAL POSITION SWITCH FUNCTION

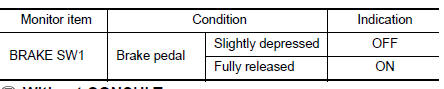

With CONSULT

With CONSULT

- Turn ignition switch ON.

- Select “BRAKE SW1” in “DATA MONITOR” mode with CONSULT.

- Check “BRAKE SW1” indication as per the following conditions.

Without CONSULT

Without CONSULT

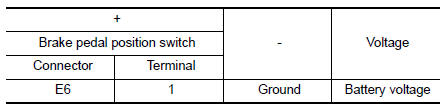

- Turn ignition switch ON.

- Check the voltage between ECM harness connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-455, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect brake pedal position switch harness connector.

- Turn ignition switch ON.

- Check the voltage between brake pedal position switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect fuse block (J/B) harness connector.

- Check the continuity between brake pedal position switch harness connector and fuse block (J/B) harness connector.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

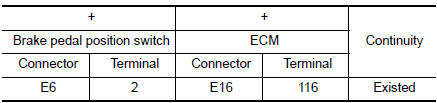

3.CHECK BRAKE PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between brake pedal position switch harness connector and ECM harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK BRAKE PEDAL POSITION SWITCH

Check brake pedal position switch. Refer to EC-456, "Component Inspection (Brake Pedal Position Switch)".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-41, "Intermittent Incident".

NO >> Replace brake pedal position switch. Refer to BR-20, "Exploded View".

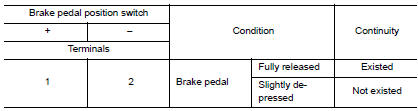

Component Inspection (Brake Pedal Position Switch)

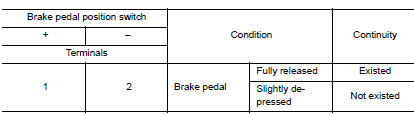

1.CHECK BRAKE PEDAL POSITION SWITCH-1

- Turn ignition switch OFF.

- Disconnect brake pedal position harness connector.

- Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK BRAKE PEDAL POSITION SWITCH-2

- Adjust brake pedal position switch installation. Refer to BR-15, "Adjustment".

- Check the continuity between brake pedal position switch terminals as per the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace brake pedal position switch. Refer to BR-20, "Exploded View".

P2610 ECM internal timer

P2610 ECM internal timer

Description

This ECM contains a timer and measures time between an ignition switch OFF

and the next ignition switch

ON. This enables the judging of the state of engine cooling at an engine start.

...

Cooling fan

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT

Turn ignition switch ON.

Perform “COOLING FAN (DUAL)” in “ACTIVE TEST” mode of “IPDM E/R”

using CO ...

Other materials:

Ducts and grilles

Exploded View

Side defroster duct (RH)

Defroster nozzle

Side defroster duct (LH)

Center ventilator duct

Heating and cooling unit assembly

Front foot duct (LH)

Front floor connecting duct (LH)

Front floor duct (LH)

Rear center ventilator duct

Adaptor duct 11 ...

Seat belt extenders

3rd row shown; 2nd row similar

Seat belt hook

When the seat belt is not in use and when folding

down the rear seats, hook the rear seat belts on

the seat belt hooks.

If, because of body size or driving position, it is

not possible to properly fit the lap/shoulder belt

and fasten it, an ex ...

Plug

Description

Replace the O-ring if oil leakage or exudes from the plug.

Exploded View

Transaxle assembly

O-ring

Plug

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: Apply CVT fluid

Removal and Installation

REMOVAL

Partially remove front fender prote ...