Nissan Rogue Service Manual: Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

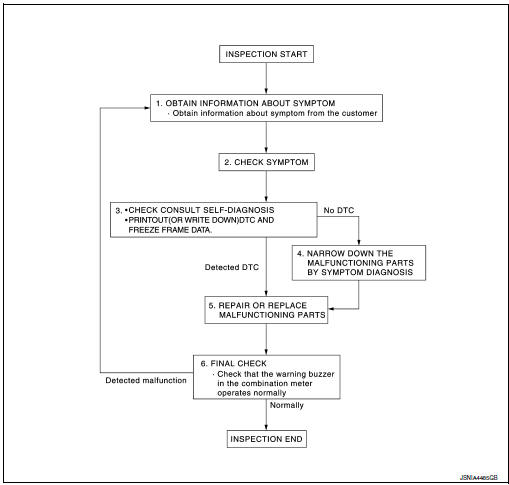

Work Flow

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

- Check the symptom based on the information obtained from the customer.

- Check if any other malfunctions are present.

> GO TO 3.

3.CHECK CONSULT SELF-DIAGNOSIS RESULTS

- Connect CONSULT and perform "self-diagnosis". Refer to WCS-27, "DTC Index".

- When DTC is detected, follow the instructions below:

- Record DTC and Freeze Frame Data.

Are self-diagnosis results normal? YES >> GO TO 4.

NO >> GO TO 5.

4.NARROW DOWN MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts.

>> GO TO 5.

5.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace malfunctioning parts.

NOTE: If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that the warning buzzer in the combination meter operates normally.

Does it operate normally? YES >> Inspection End.

NO >> GO TO 1.

Wiring diagram

Wiring diagram

Wiring Diagram

...

Other materials:

Front passenger air bag module

Exploded View

Front passenger air bag module

Steering member

Removal and Installation

WARNING:

Before servicing the SRS, turn ignition switch OFF, disconnect

both battery terminals then wait at

least three minutes.

Always work from the side of air bag module. Do ...

System description

COMPONENT PARTS

Component Parts Location

Air bag diagnosis sensor unit

AV control unit

Around view monitor control unit

Chassis control module

ABS actuator and electric unit (control

unit)

• A/C auto amp. (With auto A/C)

• Front air control (Without auto A/

C)

...

Symptom diagnosis

COMBINATION SWITCH SYSTEM SYMPTOMS

Symptom Table

Perform the data monitor of CONSULT to check for any malfunctioning

item.

Check the malfunction combinations.

Identify the malfunctioning part from the agreed combination and repair

or replace the part.

NORMAL OPERA ...