Nissan Rogue Service Manual: P052A, P052B intake valve timing control

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P052A | CAMSHAFT POSITION TIMING B1 (Cold start “A” camshaft position timing over-advanced bank 1) | There is a gap between angle of target and phase-control angle degree when the engine is in a cold condition. |

| P052B | CAMSHAFT POSITION TIMING B1 (Cold start “A” camshaft position timing over-retarded bank 1) |

POSSIBLE CAUSE

- Crankshaft position sensor

- Camshaft position sensor

- Intake valve timing control solenoid valve

- Intake valve timing intermediate lock control solenoid valve

- Accumulation of debris to the signal pick-up portion of the camshaft

- Timing chain installation

- Foreign matter caught in the oil groove for intake valve timing control

FAIL-SAFE

Device fix mode

DTC CONFIRMATION PROCEDURE

1.CHECK DTC PRIORITY

If DTC P052A or P052B is displayed with DTC P0075, first perform the trouble diagnosis for DTC P0075.

Is applicable DTC detected? YES >> Perform diagnosis of applicable. Refer to EC-191, "DTC Description".

NO >> GO TO 2.

2.PRECONDITIONING

TESTING CONDITION: Before performing the following procedure, confirm that battery voltage is 10 V or more at idle.

With CONSULT

With CONSULT

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- On the CONSULT screen, select “ENGINE” >> “DATA MONITOR” >> “COOLAN TEMP/S”.

- Check “COOLAN TEMP/S” indication value.

With GST

With GST

Follow the procedure “With CONSULT” above.

Is the value of “COOLAN TEMP/S”−5°C (23°F) and 45°C (113°F)? YES >> GO TO 3.

NO-1 [if it is below − 5°C (23°F)]>>Warm up the engine until the value of “COOLAN TEMP/S” indicates −5°C (23°F) and 45°C (113°F). And then GO TO 3.

NO-2 [if it is above 45°C (113°F)]>>Cool the engine down to the value of “COOLAN TEMP/S” indicates −5°C (23°F) and 45°C (113°F). And then GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-I

- Turn ignition switch OFF and wait at 10 seconds.

- Turn ignition switch ON.

- Set the selector lever in N range.

- Start the engine and let it idle for 20 seconds or more.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-365, "Diagnosis Procedure" NO >> INSPECTION END

Diagnosis Procedure

1.CHECK DTC PRIORITY

If DTC P052A or P052B is displayed with DTC P0075, first perform the trouble diagnosis for DTC P0075.

Is applicable DTC detected? YES >> Perform diagnosis of applicable. Refer to EC-191, "DTC Description".

NO >> GO TO 2.

2.INSPECTION START

With CONSULT>>GO TO 3.

Without CONSULT>>GO TO 4.

3.CHECK VTC POSITION

With CONSULT

With CONSULT

- Turn ignition switch ON.

- On the CONSULT screen, select “ENGINE” >> “DATA MONITOR” >> “COOLAN TEMP/S”.

- Check that the “COOLAN TEMP/S” indication value is between −5°C (23°F) and 45°C (113°F).

- Start engine and wait at least 5 seconds.

- On the CONSULT screen, select “ENGINE” >> “DATA MONITOR” >> “INT/V TIM (B1)”.

- Check that the data monitor item indicates as follows:

| Item | Value (°CA) |

| INT/V TIM (B1) | 10 ± 2 |

Is the inspection result normal? YES >> GO TO 12.

NO >> GO TO 4.

4.CHECK OIL PRESSURE WARNING LAMP

- Start engine.

- Check that oil pressure warning lamp is not illuminated.

Is oil pressure warning lamp illuminated? YES >> Refer to LU-7, "Inspection".

NO >> GO TO 5.

5.CHECK INTAKE VALVE TIMING INTERMEDIATE LOCK CONTROL SOLENOID VALVE

Perform Component Inspection of the intake valve timing intermediate lock control solenoid valve. Refer to EC-367, "Component Inspection (Intake Valve Timing Intermediate Lock Control Solenoid Valve)".

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE

Perform Component Inspection of the intake valve timing control solenoid valve. Refer to EC-366, "Component Inspection (Intake Valve Timing Control Solenoid Valve)".

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace error-detected parts.

7.CHECK CRANKSHAFT POSITION SENSOR

Perform Component Inspection of the crankshaft position sensor. Refer to EC-368, "Component Inspection (Crankshaft Position sensor)".

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

8.CHECK CAMSHAFT POSITION SENSOR

Perform Component Inspection of the camshaft position sensor. Refer to EC-368, "Component Inspection (Camshaft position sensor)".

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace error-detected parts.

9.CHECK CAMSHAFT (INTAKE)

Check the following.

- Accumulation of debris on the signal plate of camshaft front end

- Chipping signal plate of camshaft front end

Is the inspection result normal? YES >> GO TO 10.

NO >> Remove debris and clean the signal plate of camshaft front end or replace camshaft. Refer to EM-64, "Removal and Installation".

10.CHECK TIMING CHAIN INSTALLATION

Check service records for any recent repairs that may cause timing chain misalignment.

Are there any service records that may cause timing chain misalignment? YES >> Check timing chain installation. Refer to EM-45, "Removal and Installation".

NO >> GO TO 11.

11.CHECK LUBRICATION CIRCUIT

Perform “Inspection of Camshaft Sprocket (INT) Oil Groove”. Refer to EM-72, "Inspection After Installation".

Is the inspection result normal? YES >> GO TO 12.

NO >> Clean lubrication line.

12.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection (Intake Valve Timing Control Solenoid Valve)

1.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-I

- Turn ignition switch OFF.

- Disconnect intake valve timing control solenoid valve harness connector.

- Check resistance between intake valve timing control solenoid valve terminals as per the following

| Terminals | Resistance |

| 1 and 2 | 7.0 - 7.7 Ω [at 20°C (68°F)] |

| 1 or 2 and ground | ∞ Ω (Continuity should not exist) |

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace malfunctioning intake valve timing control solenoid valve. Refer to EM-44, "Exploded View".

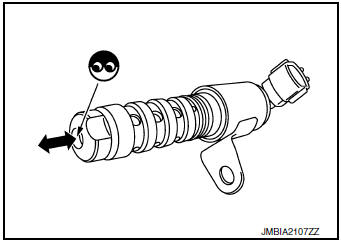

2.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE-II

1. Remove intake valve timing control solenoid valve. Refer to EM-44, "Exploded View".

2. Provide 12 V DC between intake valve timing control solenoid valve terminals 1 and 2, and then interrupt it. Check that the plunger moves as shown in the figure.

CAUTION: Never apply 12 V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in intake valve timing control solenoid valve.

NOTE: Always replace O-ring when intake valve timing control solenoid valve is removed.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace malfunctioning intake valve timing control solenoid valve. Refer to EM-44, "Exploded View".

Component Inspection (Intake Valve Timing Intermediate Lock Control Solenoid Valve)

1.CHECK INTAKE VALVE TIMING INTERMEDIATE LOCK CONTROL SOLENOID VALVE-I

- Turn ignition switch OFF.

- Disconnect intake valve timing intermediate lock control solenoid valve harness connector.

- Check resistance between intake valve timing intermediate lock control solenoid valve terminals as per the following.

| Terminals | Resistance |

| 1 and 2 | 7.0 - 7.7 Ω [at 20°C (68°F)] |

| 1 or 2 and ground | ∞ Ω (Continuity should not exist) |

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace malfunctioning intake valve timing intermediate lock control solenoid valve. Refer to EM- 44, "Exploded View".

2.CHECK INTAKE VALVE TIMING INTERMEDIATE LOCK CONTROL SOLENOID VALVE-II

- Remove intake valve timing intermediate lock control solenoid valve. Refer to EM-44, "Exploded View".

- Provide 12 V DC between intake valve timing intermediate lock

control solenoid valve terminals 1 and 2, and then interrupt it.

Check that the plunger moves as shown in the figure.

CAUTION: Never apply 12 V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in intake valve timing intermediate lock control solenoid valve.

NOTE: Always replace O-ring when intake valve timing intermediate lock control solenoid valve is removed.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace malfunctioning intake valve timing intermediate lock control solenoid valve. Refer to EM- 44, "Exploded View".

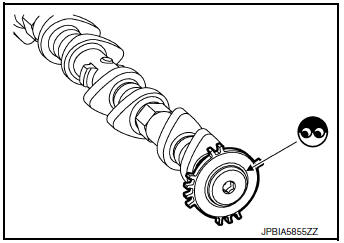

Component Inspection (Crankshaft Position sensor)

1.CHECK CRANKSHAFT POSITION SENSOR (POS)-1

- Turn ignition switch OFF.

- Loosen the fixing bolt of the sensor.

- Disconnect crankshaft position sensor (POS) harness connector.

- Remove the sensor.

- Visually check the sensor for chipping.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace crankshaft position sensor (POS). Refer to EM- 92, "Exploded View".

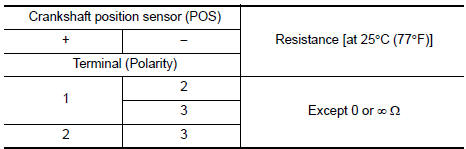

2.CHECK CRANKSHAFT POSITION SENSOR (POS)-2

Check the resistance between crankshaft position sensor (POS) terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END NO >> Replace crankshaft position sensor (POS). Refer to EM-92, "Exploded View".

Component Inspection (Camshaft position sensor)

1.CHECK CAMSHAFT POSITION SENSOR (PHASE)-1

1. Turn ignition switch OFF.

2. Loosen the fixing bolt of the sensor.

3. Disconnect camshaft position sensor (PHASE) harness connector.

4. Remove the sensor.

- Visually check the sensor for chipping.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace camshaft position sensor (PHASE).

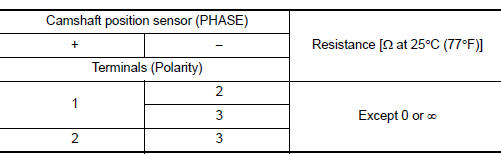

2.CHECK CAMSHAFT POSITION SENSOR (PHASE)-2

Check the resistance camshaft position sensor (PHASE) terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace camshaft position sensor (PHASE). Refer to EM-64, "Removal and Installation".

P0524 engine oil pressure

P0524 engine oil pressure

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0524

ENGINE OIL PRESSURE

(Engine oil pressure too ...

P0603, P062F ECM

P0603, P062F ECM

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0603

ECM BACK UP/CIRCUIT

[Internal Control Module ...

Other materials:

NISSAN Voice Recognition System

(if so equipped)

The NISSAN Voice Recognition system allows

hands-free operation of the systems equipped on

this vehicle, such as the phone and navigation

systems.

To operate NISSAN Voice Recognition, press

the button located on the steering

wheel.

When prompted, speak the command for the

system you wi ...

ID registration procedure

Description

This procedure must be performed after replacement of a tire pressure sensor

or BCM.

Work Procedure

TPMS ID registration can be performed using one of the following procedures:

Transmitter Activation tool [KV48105501 (J-45295-A)] with CONSULT

(preferred method)

...

Luggage trim

Exploded View

WITH THIRD ROW SEAT

Tonneau cover (if equipped)

Strap (LH/RH)

Luggage floor finisher (RH)

Luggage floor center finisher

Luggage floor finisher (LH)

Luggage side lower finisher (LH)

Luggage side upper finisher (LH)

Hooks (LH/RH)

Lug ...