Nissan Rogue Service Manual: P0447 EVAP canister vent control valve

DTC Description

DTC DETECTION LOGIC

| DTC No. | CONSULT screen terms (Trouble diagnosis content) | DTC detecting condition |

| P0447 | VENT CONTROL VALVE (Evaporative emission system vent control circuit open) | An improper voltage signal is sent to ECM through EVAP canister vent control valve. |

POSSIBLE CAUSE

- Harness or connectors (EVAP canister vent control valve circuit is open or shorted.)

- EVAP canister vent control valve

FAIL-SAFE

Not applicable

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

- Turn ignition switch OFF and wait at least 10 seconds.

- Turn ignition switch ON.

- Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION: Before performing the following procedure, confirm battery voltage is more than 11 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

- Start engine and wait at least 8 seconds.

- Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-319, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.INSPECTION START

Do you have CONSULT? Do you have CONSULT? YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK EVAP CANISTER VENT CONTROL VALVE CIRCUIT

With CONSULT

With CONSULT

- Turn ignition switch OFF and then turn ON.

- Select “VENT CONTROL/V” in “ACTIVE TEST” mode of “ENGINE” using CONSULT.

- Touch “ON/OFF” on CONSULT screen.

- Check for operating sound of the valve.

Clicking sound should be heard.

Is the inspection result normal? YES >> GO TO 7.

NO >> GO TO 3.

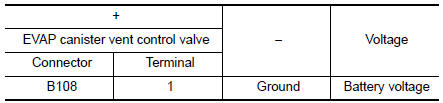

3.CHECK EVAP CANISTER VENT CONTROL VALVE POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect EVAP canister vent control valve harness connector

- Turn ignition switch ON.

- Check the voltage between EVAP canister vent control valve harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.CHECK EVAP CANISTER VENT CONTROL VALVE POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R harness connector.

- Check the continuity between EVAP canister vent control valve harness connector and IPDM E/R harness connector.

- Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

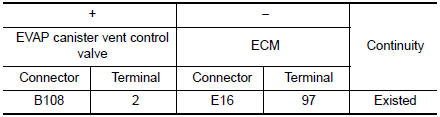

5.CHECK EVAP CANISTER VENT CONTROL VALVE OUTPUT SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Check the continuity between EVAP canister vent control valve harness connector and ECM harness connector.

- Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK RUBBER TUBE FOR CLOGGING

- Disconnect rubber tube connected to EVAP canister vent control valve.

- Check the rubber tube for clogging.

Is the inspection result normal? YES >> GO TO 7.

NO >> Clean the rubber tube using an air blower.

7.CHECK EVAP CANISTER VENT CONTROL VALVE

Check the EVAP canister vent control valve. Refer to EC-321, "Component Inspection".

Is the inspection result normal? YES >> GO TO 8.

NO >> Replace EVAP canister vent control valve. Refer to FL-21, "Removal and Installation"

8.CHECK INTERMITTENT INCIDENT

Refer to GI-41, "Intermittent Incident".

>> INSPECTION END

Component Inspection

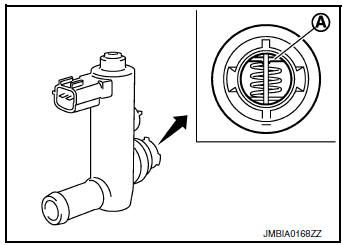

1.CHECK EVAP CANISTER VENT CONTROL VALVE-1

- Turn ignition switch OFF.

- Remove EVAP canister vent control valve from EVAP canister.

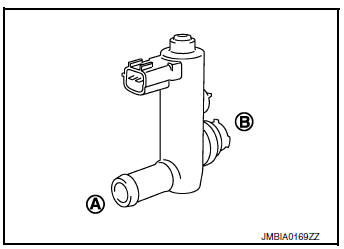

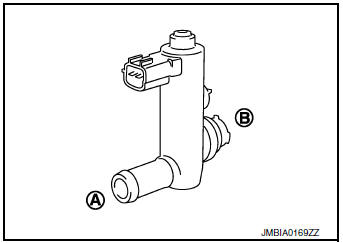

- Check portion A of EVAP canister vent control valve for being rusted.

Is it rusted? YES >> Replace EVAP canister vent control valve. Refer to FL- 21, "Removal and Installation".

NO >> GO TO 2.

2.CHECK EVAP CANISTER VENT CONTROL VALVE-2

With CONSULT

With CONSULT

- Reconnect harness connectors disconnected.

- Turn ignition switch ON.

- Perform “VENT CONTROL/V” in “ACTIVE TEST” mode of “ENGINE” using CONSULT.

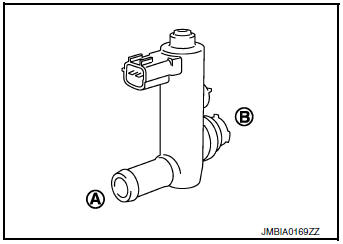

- Check air passage continuity and operation delay time.

Make sure new O-ring is installed properly.

| Condition (VENT CONT/V) | Air passage continuity between A and B |

| ON | Not existed |

| OFF | Existed |

Operation takes less than 1 second.

Without CONSULT

Without CONSULT

Check air passage continuity and operation delay time under the following conditions.

Make sure new O-ring is installed properly.

| Condition | Air passage continuity between A and B |

| 12 V direct current supply between terminals 1 and 2 | Not existed |

| OFF | Existed |

Operation takes less than 1 second.

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace EVAP canister vent control valve. Refer to FL-21, "Removal and Installation".

3.CHECK EVAP CANISTER VENT CONTROL VALVE-3

With CONSULT

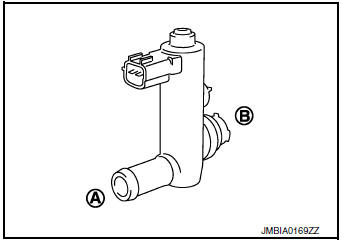

- Clean the air passage [portion to ] A of B EVAP canister vent control valve using an air blower.

- Perform “VENT CONTROL/V” in “ACTIVE TEST” mode of “ENGINE” using CONSULT.

- Check air passage continuity and operation delay time.

Make sure new O-ring is installed properly.

| Condition (VENT CONT/V) | Air passage continuity between A and B |

| ON | Not existed |

| OFF | Existed |

Operation takes less than 1 second.

Without CONSULT

- Clean the air passage [portion A to B] of EVAP canister vent control valve using an air blower.

- Check air passage continuity and operation delay time under the following conditions.

Make sure new O-ring is installed properly.

| Condition | Air passage continuity between A and B |

| 12 V direct current supply between terminals 1 and 2 | Not existed |

| OFF | Existed |

Operation takes less than 1 second.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace EVAP canister vent control valve. Refer to FL-21, "Removal and Installation".

P0444, P0445 EVAP canister purge volume control solenoid

P0444, P0445 EVAP canister purge volume control solenoid

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0444

PURG VOLUME CONT/V

(Evaporative emission sys ...

P0448 EVAP canister vent control valve

P0448 EVAP canister vent control valve

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0448

VENT CONTROL VALVE

(Evaporative emission sys ...

Other materials:

U1001 CAN comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...

Battery

Exploded View

Battery tray liner

Battery frame

Battery

Battery rod

Battery cover

Battery tray

Front

Removal and Installation (Battery)

REMOVAL

Pull back cover of battery positive terminal.

Loosen the battery terminal nuts and disconnect the battery ...

P0847 transmission fluid pressure SEN/SW B

DTC Description

DTC DETECTION LOGIC

DTC

CONSULT screen terms

(Trouble diagnosis content)

DTC detection condition

P0847

FLUID PRESS SEN/SW B

(Transmission Fluid Pressure Sensor/Switch B

Circuit Low)

When all of the following conditions are satisfied and this sta ...