Nissan Rogue Service Manual: Oil pan

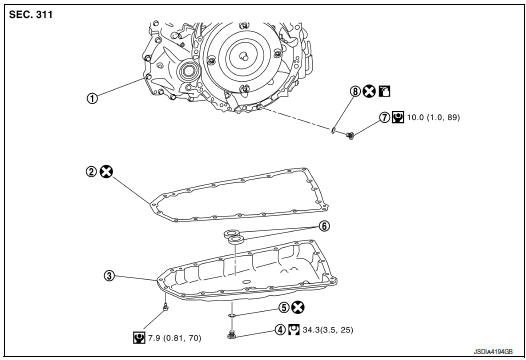

Exploded View

COMPONENT PARTS LOCATION

- Transaxle assembly

- Oil pan gasket

- Oil pan

- Drain plug

- Drain plug gasket

- Magnet

- Overflow plug

- O-ring

Always replace after every

disassembly.

Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Apply CVT fluid

: Apply CVT fluid

Removal and Installation

REMOVAL

- Remove engine under cover. Refer to TM-205, "Removal and Installation".

- Remove drain plug from oil pan and then drain the CVT fluid.

- Remove drain plug gasket.

- Remove the oil pan bolts, and then remove the oil pan and oil pan gasket.

- Remove the magnets from the oil pan.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

- Do not reuse oil pan gasket.

- Do not reuse drain plug gasket.

- Do not reuse O-ring.

- Completely clean the iron powder from the magnet area of oil pan and the magnets.

Install the oil pan to the transaxle case with the following procedure.

- Install the oil pan gasket to the oil pan.

CAUTION: Completely wipe out any moisture, oil, and old gasket from the oil pan gasket surface and bolt hole of oil pan and transaxle case.

- Install the oil pan assembly to the transaxle case, and then temporarily tighten the oil pan bolt.

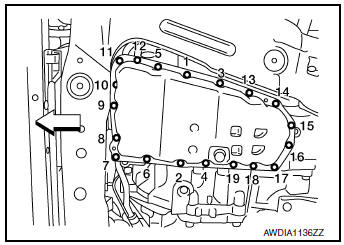

- Tighten the oil pan bolts in the order shown to the specified torque.

: Front

: Front

- Tighten the oil pan bolts again clockwise from (1) shown to the specified torque.

Inspection

INSPECTION AFTER REMOVAL

Check oil pan for foreign material.

- If a large amount of worn material is found, clutch plate may be worn.

- If iron powder is found, bearings, gears, or clutch plates may be worn.

- If aluminum powder is found, bushing may be worn, or chips or burrs of aluminum casting parts may enter.

Check points where wear is found in all cases.

INSPECTION AFTER INSTALLATION

Check the CVT fluid level and leakage. Refer to TM-190, "Inspection".

Air breather

Air breather

Exploded View

Air breather

Air breather hose

Air breather tube

Transaxle assembly

: Vehicle front

Removal and Installation

REMOVAL

Remove air cleaner and air duct. Refer ...

Input speed sensor

Input speed sensor

Exploded View

Input speed sensor

O-ring

Transaxle assembly

: Always replace after every

disassembly.

: N·m (kg-m, in-lb)

: Apply CVT fluid

Removal and Installation

REMOVAL

...

Other materials:

U1000 CAN COMM CIRCUIT

Description

CAN communication allows a high rate of information transmission through the

two communication lines

(CAN-H line and CAN-L line) connecting various control units in the system. Each

control unit transmits/

receives data but selectively reads required data only.

DTC Logic

DTC DET ...

Front passenger air bag module

Exploded View

Front passenger air bag module

Steering member

Removal and Installation

WARNING:

Before servicing the SRS, turn ignition switch OFF, disconnect

both battery terminals then wait at

least three minutes.

Always work from the side of air bag module. Do ...

Unit removal and installationEMBER

REAR SUSPENSION M

Exploded View

Rear suspension member

Suspension member stay

(RH)

Suspension member stay (LH)

Bound bumper

Front

Removal and Installation - FWD

REMOVAL

Remove wheel and tires using power tool. Refer to WT-60, "Exploded

Vie ...