Nissan Rogue Service Manual: Fuel pump

Description

| Sensor | Input signal to ECM | ECM Function | Actuator |

| Crankshaft position sensor (POS) Camshaft position sensor (PHASE) |

Engine speed* | Fuel pump control | Fuel pump relay ↓ Fuel pump |

| Battery | Battery voltage* |

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for several seconds after the ignition switch is turned ON to improve engine start ability. If the ECM receives a engine speed signal from the camshaft position sensor (PHASE), it knows that the engine is rotating, and causes the pump to operate. If the engine speed signal is not received when the ignition switch is ON, the engine stalls. The ECM stops pump operation and prevents battery discharging, thereby improving safety. The ECM does not directly drive the fuel pump. It controls the ON/OFF fuel pump relay, which in turn controls the fuel pump.

| Condition | Fuel pump operation |

| Ignition switch is turned to ON | Operates for 1 second. |

| Engine running and cranking | Operates. |

| When engine is stopped | Stops in 1.5 seconds. |

| Except as shown above | Stops. |

Component Function Check

1.CHECK FUEL PUMP FUNCTION

- Turn ignition switch ON.

- Pinch fuel feed hose with two fingers.

Fuel pressure pulsation should be felt on the fuel feed hose for 1 second after ignition switch is turned ON.

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-467, "Diagnosis Procedure".

Diagnosis Procedure

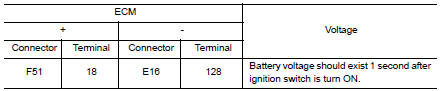

1.CHECK FUEL PUMP RELAY CONTROL SIGNAL

- Turn ignition switch ON.

- Check the voltage between ECM harness connector.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

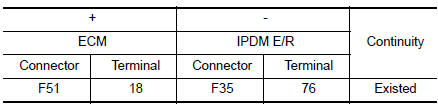

2.CHECK FUEL PUMP RELAY CONTROL SIGNAL CIRCUIT

- Turn ignition switch OFF.

- Disconnect ECM harness connector.

- Disconnect IPDM E/R harness connector.

- Check the continuity between ECM harness connector and IPDM E/R harness connector.

Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace error-detected parts.

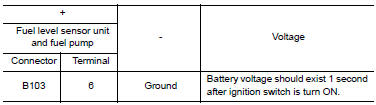

3.CHECK FUEL PUMP POWER SUPPLY

- Turn ignition switch OFF.

- Disconnect ÔÇťfuel level sensor unit and fuel pumpÔÇŁ harness connector.

- Turn ignition switch ON.

- Check the voltage between ÔÇťfuel level sensor unit and fuel pumpÔÇŁ harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

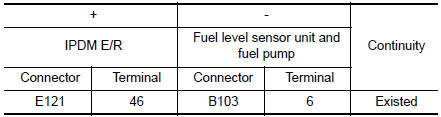

4.CHECK FUEL PUMP POWER SUPPLY CIRCUIT

- Turn ignition switch OFF.

- Disconnect IPDM E/R harness connector.

- Check the continuity between IPDM E/R harness connector and ÔÇťfuel level sensor unit and fuel pumpÔÇŁ harness connector.

- Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace error-detected parts.

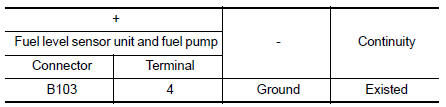

5.CHECK FUEL PUMP GROUND CIRCUIT

- Check the continuity between ÔÇťfuel level sensor unit and fuel pumpÔÇŁ and ground.

- Also heck harness for short to power.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

6.CHECK FUEL PUMP

Refer to EC-469, "Component Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace ÔÇťfuel level sensor unit and fuel pumpÔÇŁ. Refer to FL-6, "Removal and Installation".

7.CHECK INTERMITTENT INCIDENT

Perform GI-41, "Intermittent Incident".

Is the inspection result normal? YES >> Replace IPDM E/R. Refer to PCS-35, "Removal and Installation".

NO >> Repair or replace harness or connectors.

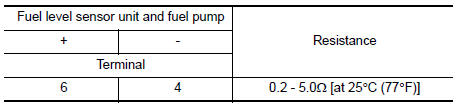

Component Inspection

1.CHECK FUEL PUMP

- Turn ignition switch OFF.

- Disconnect ÔÇťfuel level sensor unit and fuel pumpÔÇŁ harness connector.

- Check resistance between ÔÇťfuel level sensor unit and fuel pumpÔÇŁ terminals as follows.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace ÔÇťfuel level sensor unit and fuel pumpÔÇŁ. Refer to FL-6, "Removal and Installation".

Fuel injector

Fuel injector

Component Function Check

1.INSPECTION START

Turn ignition switch to START.

Are any cylinders ignited?

YES >> GO TO 2.

NO >> Proceed to EC-464, "Diagnosis Procedure".

2. ...

Ignition signal

Ignition signal

Component Function Check

1.INSPECTION START

Turn ignition switch OFF, and restart engine.

Does the engine start?

YES-1 >> With CONSULT: GO TO 2.

YES-2 >> Without CONSULT: GO TO 3. ...

Other materials:

P0444, P0445 EVAP canister purge volume control solenoid

DTC Description

DTC DETECTION LOGIC

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

P0444

PURG VOLUME CONT/V

(Evaporative emission system purge control

valve circuit open)

An excessively low voltage signal is sent to ECM through ...

Sample/Wiring Diagram -Example-

Each section includes wiring diagrams.

Description

Number

Item

Description

1

Power supply

This means the power supply of fusible link or fuse.

2

Fuse

ÔÇť/ÔÇŁ means the fuse.

3

Current rating of fusible

...

Rear window defogger relay

Description

Power is supplied to the rear window defogger with BCM control.

Component Function Check

1. CHECK REAR WINDOW DEFOGGER RELAY POWER SUPPLY CIRCUIT

Check that an operation noise of rear window defogger relay [located in fuse

block (J/B)] can be heard when

turning the rear window def ...