Nissan Rogue Service Manual: Removal and installation

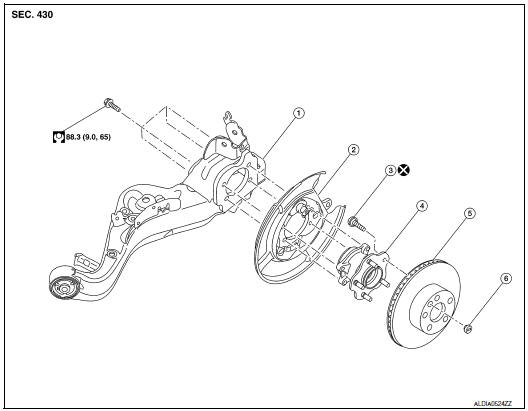

REAR WHEEL HUB

Exploded View

- Suspension arm

- Back plate

- Wheel stud

- Wheel hub and bearing

- Disc brake rotor

- Plug

Removal and Installation

REMOVAL

Wheel Hub and Bearing

- Remove the wheel and tire using power tool. Refer to WT-57, "Adjustment".

- Remove the bolt and separate the rear wheel sensor from the wheel hub and bearing. Refer to BRC-133, "REAR WHEEL SENSOR : Exploded View".

CAUTION:

- Failure to separate the rear wheel sensor from the wheel hub and bearing may result in damage to the rear wheel sensor.

- Pull out the rear wheel sensor, being careful to turn it as little as possible. Do not pull on wheel sensor harness.

- Remove torque member bolts using power tool, leaving the brake

hose attached. Position brake caliper

aside with wire. Refer to BR-42, "BRAKE CALIPER ASSEMBLY : Exploded View".

CAUTION: Do not depress brake pedal while brake caliper is removed.

- Put alignment marks on the disc brake rotor and on the wheel hub and

bearing. Remove the disc brake

rotor. Remove disc brake rotor.

CAUTION: Do not drop disc brake rotor.

- Remove the hub bolts and the wheel hub and bearing.

- If necessary, remove the wheel studs (1) from the wheel hub and bearing using a suitable tool (A).

CAUTION:

- Remove the wheel studs only when necessary.

- Do not hammer the wheel studs or damage to the wheel hub and bearing may occur.

- Pull out the wheel studs in a direction perpendicular to the wheel hub and bearing.

- Inspect the components. Refer to RAX-8, "Inspection".

INSTALLATION

Installation is in the reverse order of removal.

- Place a washer (A) as shown to install the wheel studs (1) by using the tightening force of the nut (B).

CAUTION:

- Do not reuse the wheel stud.

- Check that there is no clearance between the wheel stud and the wheel hub and bearing.

- Before installing, make sure there is no foreign material such as iron fragments adhered to the pick-up part of the rear wheel sensor.

- When installing, make sure there is no foreign material such as iron fragments on and in the hole in the wheel hub and bearing for the rear wheel sensor. Make sure no foreign material has been caught in the sensor rotor. Remove any foreign material and clean the mount.

- Install the rear wheel sensor to the wheel hub and bearing. Refer to BRC-133, "REAR WHEEL SENSOR : Exploded View".

- Align the matching marks made during removal when reusing the disc brake rotor.

- Check that the wheel hub and bearing operates smoothly.

- Perform the inspection after installation. Refer to RAX-8, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check wheel hub and bearing for wear, cracks, and damage. Replace if necessary.

INSPECTION AFTER INSTALLATION

- Adjust parking brake operation (stroke). Refer to PB-4, "Inspection and Adjustment".

- Check wheel alignment. Refer to RSU-6, "Inspection".

- Adjust neutral position of steering angle sensor. Refer to BRC-70, "Work Procedure".

Periodic maintenance

Periodic maintenance

REAR WHEEL HUB AND HOUSING

Inspection

INSPECTION

Make sure the conditions (looseness, back lash) of each component and

component conditions (wear, damage)

are normal.

WHEEL HUB AND BEARING INSP ...

Service data and specifications (SDS)

Service data and specifications (SDS)

Wheel Bearing

...

Other materials:

Basic inspection

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Work flow

STEP

DESCRIPTION

STEP 1

Get detailed information about the conditions and the

environment when the incident occurred.

The following are key pieces of information required to make a good

analysis:

WH ...

System description

COMPONENT PARTS

Component Parts Location

No.

Component

Description

1

Push-button ignition

switch1

Push-button ignition switch (push switch) is pressed (ON), and

transmits status signal to BCM

and IPDM E/R.

Ignition switch2

Ignition ...

Basic inspection

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

WORK FLOW

DETAILED FLOW

1. REVIEW CUSTOMER COMPLAINT

Review customer complaint. Try to obtain detailed information about the

conditions when the symptom occurs.

>> GO TO 2.

2. VERIFY THE SYMPTOM

Verify the symptom by performing an operation ...